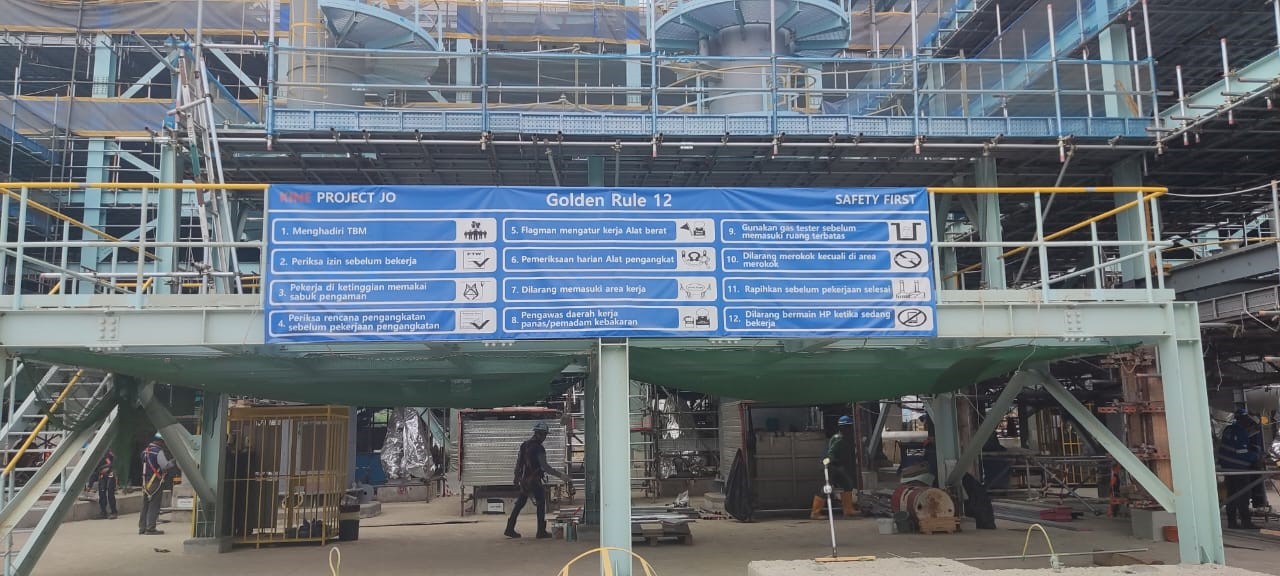

Cilegon, Indonesia – Safety is a fundamental value in every major industrial project, especially in the manufacturing and chemical sectors, where potential risks can be very high. Achieving zero accidents is an exceptional accomplishment. A real example of commitment to safety is the Steel Structure Mechanical Piping Work project for Lotte Chemical Indonesia carried out by PT Swadaya Graha, which successfully achieved Zero Accident in over 500,000 work hours. This is not only an impressive achievement but also an inspirational example of how a company and a project team can prioritize safety in all aspects.

The Importance of Zero Accident

When a project achieves Zero Accident, it demonstrates that prevention and protection measures have been taken seriously, and there is a safety culture at all levels. Some key contributing factors include:

- Safety Awareness as a Priority (Safety Culture)From the beginning of the project, PT Swadaya Graha has communicated to all personnel and contractors the importance of safety awareness in every aspect of their work through daily Tool Box Meetings (TBMs) before starting work. They actively promote a safety culture by conducting regular training, safety briefings, and running reward programs for teams performing well in safety aspects.

- Risk Assessment and Management (Regular Inspection)Before commencing work, PT Swadaya Graha conducts comprehensive risk assessments to identify and address potential hazards in the workplace. This assessment helps them determine appropriate risk control measures and ensures that all safety equipment, protective devices, and procedures are functioning correctly.

- Safety Equipment and GearPT Swadaya Graha ensures that all workers are equipped with the appropriate safety gear for the tasks at hand. They make sure this equipment is well-maintained and in good working condition before use.

- Supervision and ReportingSafety supervision teams appointed by PT Swadaya Graha actively monitor activities in the field. They ensure that all safety protocols are followed and provide regular feedback to management. Additionally, a transparent incident reporting system is implemented to ensure that every incident or accident is promptly addressed and learned from to prevent similar occurrences in the future.

- Training and Workforce QualificationsPT Swadaya Graha places a high emphasis on training and qualifications of the workforce involved in this project. All workers must have a strong understanding of safety procedures and the required certifications for specific tasks. They also ensure that each worker has knowledge of safe equipment usage.

- Respect for Industry Regulations and StandardsThroughout the project, PT Swadaya Graha is committed to respecting industry safety regulations and standards. They always ensure that the project complies with government regulations and the latest safety standards in the construction sector, such as:

- Open and Responsive CommunicationSafety is a collective responsibility, and PT Swadaya Graha encourages open communication among all relevant parties. Workers, supervisors, management, and contract partners share information and feedback to ensure that every safety issue can be identified and addressed promptly.

This demonstrates that with strong commitment, proper training, and a robust safety culture, zero accidents can be achieved in complex and high-risk projects. This achievement also serves as an inspiration for other industries and similar projects to prioritize safety and the well-being of workers above all else.

Conclusion

Achieving Zero Accident in over 500,000 work hours on Lotte Chemical Indonesia’s Steel Structure Mechanical Piping Work project in Cilegon is a real-life example of how commitment to safety, proper training, and a strong safety culture can produce exceptional results. This project is planned to continue until November 30, 2024. PT Swadaya Graha’s contributions to the construction phase of the project for the Aromatics process area—benzene, toluene, and xylene (BTX)—include constructing steel structure pipe racks and equipment totaling 4,000 MT of mechanical installation. This involves using cranes with capacities of up to 200 MT and installing over 170,000 dia-inch of piping, with the work executed by more than 300 direct and indirect workers. In addition to pursuing success in completing this project according to the specified schedule and specifications, PT Swadaya Graha also prioritizes workplace safety as the top priority. This serves as evidence that Zero Accident is not an unattainable goal but rather a result of collective effort, discipline, and a focus on human well-being.